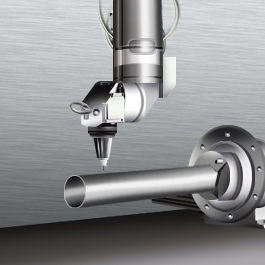

Tube Cutting

Contract Tube Cut-Off

We specialize in contract tube cutting of all workable alloys, including stainless steel hypodermic tubing (hypotube), exotics, brass & copper. We use a multi-stage fabrication process to shear cut tubular parts with no scrap between cuts. Most end forming is accomplished during the tube cut-off process. Tubular parts are also bent without kinking.

- Burr-free shear cut ends; finishing is available to remove sharp edges

- Most cut tube end configurations can be done simultaneously

- Clean, square cut edges, with little OD/ID distortion and no collapse

- Precision tube fabricating & bending services – up to billions of parts per run

REQUEST A

SECURE QUOTE

Our tube fabrication & cutting experts are ready to create your quote

Four Slide Products provided accurate delivery information not only in the quoting stage but through the production phase.

Duane D. Riha,

Legacy Technologies, Inc.

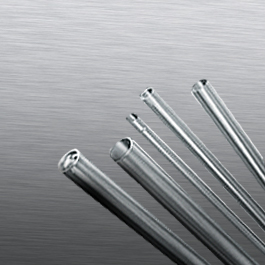

Precision Cut Tubing

Our custom tube shear cutting machines can cut, bend, and end form your tubular parts as short as 0.020″ ± 0.001″ with little OD/ID distortion, burr-free, and with no material loss between cuts. Square cut edges, with most end forming achieved in-process. Runs from hundreds to billions of parts.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

Contract Tube Cutting

Contract tube cutting of all workable alloys, including exotics, stainless steel, Rodar/Kovar®, 52 Alloy, brass and copper. We’ll cut your tubing or source tubing for you (including custom tube sizes). End configurations are done simultaneously. Tubular parts are bent without kinking, with little distortion and no collapse to the outside or inside diameters.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

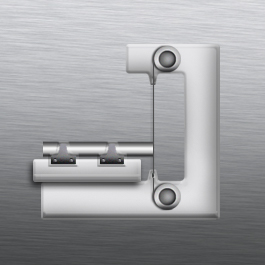

Shear-Cut Tubular Parts

Fast and efficient, shear cutting can be combined with other forming processes to save time and reduce costs. Shear cutting produces no material loss between parts, leading to significant cost savings. With tight tolerances and square cuts, shear cutting achieves extremely high production rates and is scalable for high-volume runs.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

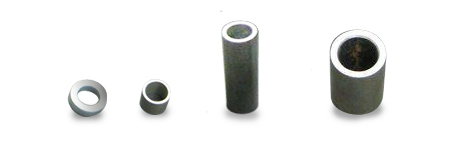

Metal Spacers and Bushings

Precision-cut metal spacers and bushings for stand-offs, sleeves, axles, pins, distance bushings, and custom components. Shear cutting creates burr-free, square cut edges with no material loss between cuts. Lengths range from 0.020″ to 18″, with tolerances to ± 0.001.” Runs are scalable from hundreds to billions of parts.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

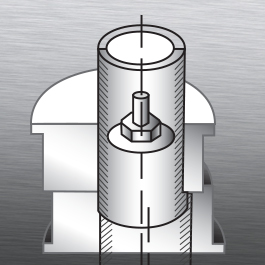

Supported Shear Cutting of Tubing

Shear cutting alone (without ID support) would introduce some inner diameter distortion. Innovative in-house tooling at Four Slide Products delivers all of the benefits of shear cutting plus internal and external support to eliminate distortion. Suitable for all workable alloys, with diameters up to 1/2″ x 0.020″ wall standard (or larger upon request).

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

Electro-Chemical Tube Cutting

The Electro-Chemical cutting process consists of an abrasive/conductive blade, a 12 volt DC power source and an electrolyte solution. The DC current flows from the work piece through the electrolyte to the blade. This provides deburring through a reverse plating process. Most electrically conductive materials are suitable, however some are better suited due to their conductive properties.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

Shear Tube Cutting vs. Laser Tube Cutting

Shear tube cutting is more affordable than laser tube cutting. In addition, lasers can only perform one function: cutting. As a result, additional fabrication steps such as bending and end forming must be setup separately. Therefore, we recommend shear tube cutting for your primary tube fabrication needs. Customers who require etching or labeling can then schedule laser tube cutting as a secondary operation through another vendor.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

Fabricators of Shear-Cut Precision Small Tubular Parts

We specialize in contract tube cutting of all workable alloys including stainless steel hypodermic tubing (hypotube), exotics, brass and copper, 52 Alloy, Rodar/Kovar®. We shear-cut tubular parts with no scrap or material loss between parts. Most end forming and machining can also be accomplished during the tube cut-off process.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

Four Slide Products Inc.

A Custom Manufacturer of Precision Cut Tubular Parts

Contract tube cutting of all workable alloys including Stainless, 52 Alloy, Rodar/Kovar®, brass & copper for formed tubular parts. Most end configurations can be achieved simultaneously. Tubular parts are bent without kinking, little distortion and no collapse on the outside or inside diameters. Custom tooling is also available.