TUBE END FORMING AND FABRICATION

We specialize in the contract tube cutting of all workable alloys including stainless steel hypodermic tubing (hypotube), exotics, brass & copper. We use a multi-stage fabrication process to shear cut tubular parts with no material loss. Most end forming can be done during the tube cut-off process.

- Common and custom end forming and part machining options available

- Most end configurations can be achieved during the tube cut-off process

- Minimal distortion or collapse to the outside or inside diameters

- Precision tube fabricating & bending services – up to billions of parts

REQUEST A

SECURE QUOTE

Our tube fabrication & cutting experts are ready to create your quote

Four Slide Products provided accurate delivery information not only in the quoting stage but through the production phase.

Duane D. Riha,

Legacy Technologies, Inc.

Tube Bending

We cut, bend, and end-form most small tubular parts in one fabrication process, using our custom shear cutting machines. We can source all standard tube sizes and hypodermic tube gauges, as well as custom tube sizes upon request. We cut and form all workable alloys including exotic metals.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

Custom Tube Fabrication

Custom parts fabrication for tubing up to 0.625″ OD x 0.020″ wall thickness, including hypotube. Lengths range from 0.020″ to 18″, with tolerances to ±0.001 inch. Square cut edges are achieved with no material loss, and little OD/ID distortion. End forming & finishing are also available.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

Custom Miniature Tubing

Custom miniature tubing parts up to 0.625″ OD x 0.020″ wall thickness. Lengths range from 0.020″ to 18″, with tolerances to ±0.001″. We cut and end form most workable alloys. Shear cut square cut edges are achieved with no material loss and minimal OD/ID distortion. Simultaneous end forming is also available.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

Metal Spacers and Bushings

Metal spacers and bushings can be fabricated from all workable alloys, up to 0.625″ OD x 0.020″ wall thickness. Lengths range from 0.020″ to 18″, with tolerances to ±0.001″. Runs are scalable from hundreds of parts to billions. Square cut edges are achieved with no material loss, and minimal OD/ID distortion. Simultaneous end forming is also available.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

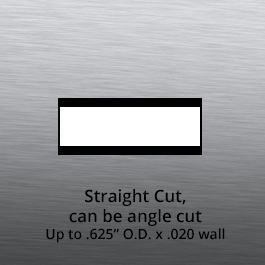

Straight Cut Tube

Our unique shear cutting process produces square cut edges with no material loss, and little OD/ID distortion. Most end forming can be performed simultaneously. All workable alloys, up to 0.625″ OD x 0.020″ wall thickness. Lengths from 0.020″ to 18″ or longer. Tolerances to ±0.001″. Runs from hundreds of parts to billions.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

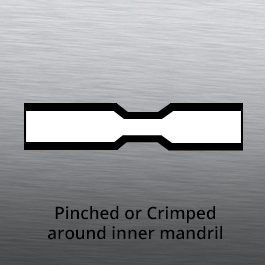

Pinched or Crimped Ends

Our unique tubular parts forming and cutting machines can pinch or crimp small tubular parts during the tube cutting process. Our fully-supported tube shear cutting and crimping equipment produces square cut edges and minimal OD/ID distortion. We can efficiently produce high-volume runs, fabricating hundreds to billions of parts to your exact specifications.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

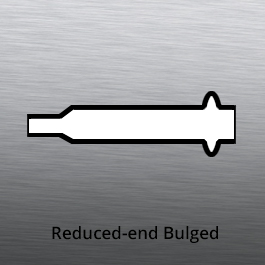

Tube Forming – Reduced End with Bulge

We manufacture precision cut tubular parts with reduced-ends (multiple forms/combinations), bulged to your specifications, made from most workable alloys.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

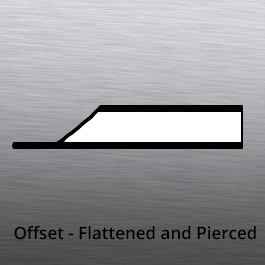

Offset Flattened and Pierced

Precision cut tubing center-flattened and pierced to your specifications. All workable alloys, up to 0.090″ OD x 0.020″ wall thickness. Lengths range from 0.125″ to 0.500″, with tolerances to ±0.001″. We can source materials for you or work with yours. High-volume runs are scalable from hundreds to billions of parts.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

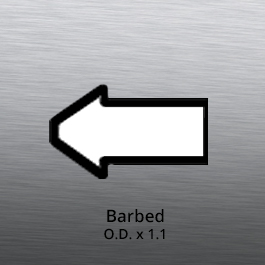

Tube End Forming – Barbed End

Precision cut tubes with barbed ends. Barbed end forming can be performed simultaneously with tube cut-off process in most cases. Ends can be barbed up to 1.4 times the outer diameter, depending on the material type and geometry.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

Tube Forming – Bulged Tubing

Cut tubular parts can be bulged up to 1.4 times the outer diameter, depending on specified part geometry and the material selection.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

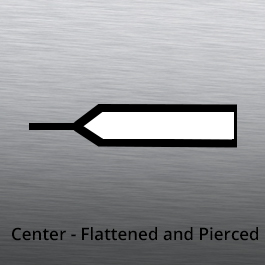

Center Flattened and Pierced

Cut tubular parts can be end flattened and pierced as desired. Most end forming can be performed simultaneously during the tube cut off and part fabrication process.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

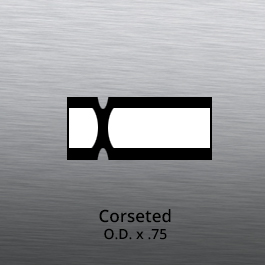

Corseted Tubing or Constant Rolled/Grooved Tubing

Cut tubular parts can be corseted or constant rolled/grooved to your specifications, down to 75% of the tube’s outer diameter, fabricated from most workable alloys.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

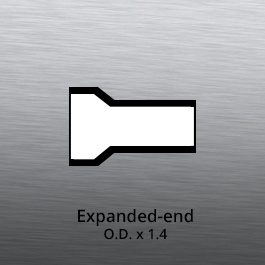

Tube End Forming – Expanded End

End forming options for cut tubular parts includes end expanding. We’re able to fabricate expanded ends to 1.4 times the outer diameter, depending on the material selection and desired geometry. Contact our engineering support team for assistance designing expanded end tubular parts for manufacturing.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

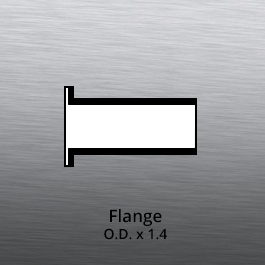

Tube End Forming – Flanged End

Tubular part end-forming options include flanged ends up to 1.4 times the tube’s outer diameter, depending on the part geometry and specifications. Let our experienced engineering team specify the optimal material stock for the most economical fabrication of your cut tube components.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

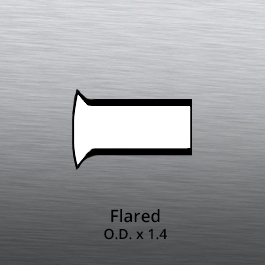

Tube End Forming – Flared End

Tubular part end-forming options include flaring of ends up to 1.4 times the tube’s outer diameter, depending on the material. Flared ends are manufactured to your specifications. Let our experienced engineering team specify the optimal material stock for the most economical fabrication of your cut tube components.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

Tube End Forming – Inside Diameter Radius

Tube end forming options include adding an inside diameter radius to tube ends, up to 0.5 times the tube’s wall thickness in most cases.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

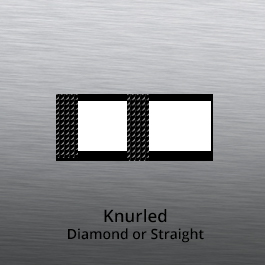

Tube Forming – Knurled

Tube forming options include knurled ends or sections, according to your specifications. Diamond knurled or straight knurled patterns available.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

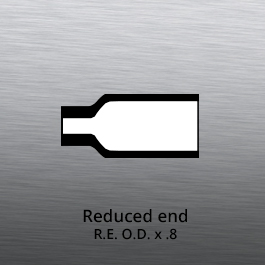

Tube End Forming – Reduced End

Tubular part end-forming options include reduced ends down to 0.8 times the tube’s outer diameter, depending on the material. Reduced ends are manufactured to your specifications. Let our experienced engineering team specify the optimal material stock for the most economical fabrication of your cut tube components.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

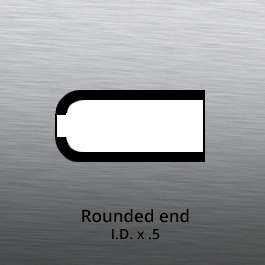

Tube End Forming – Rounded End

Cut tubular part ends can also be rounded. Rounded end formations for tubular parts down to 0.5 times the tubing inner diameter are available and can be formed according to your exact specifications.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

Four Slide Products Inc.

A Custom Manufacturer of Precision Cut Tubular Parts

Contract tube cutting of all workable alloys including exotics, brass & copper for formed tubular parts. Most end configurations can be achieved simultaneously. Tubular parts are bent without kinking, with little distortion and no collapse on the outside or inside diameters. Custom tooling is also available.